Powerbait

105 Products

-

PowerBait® Sparkle Crappie Nibbles

$5.99 -

PowerBait® Trout Dip

$7.99 -

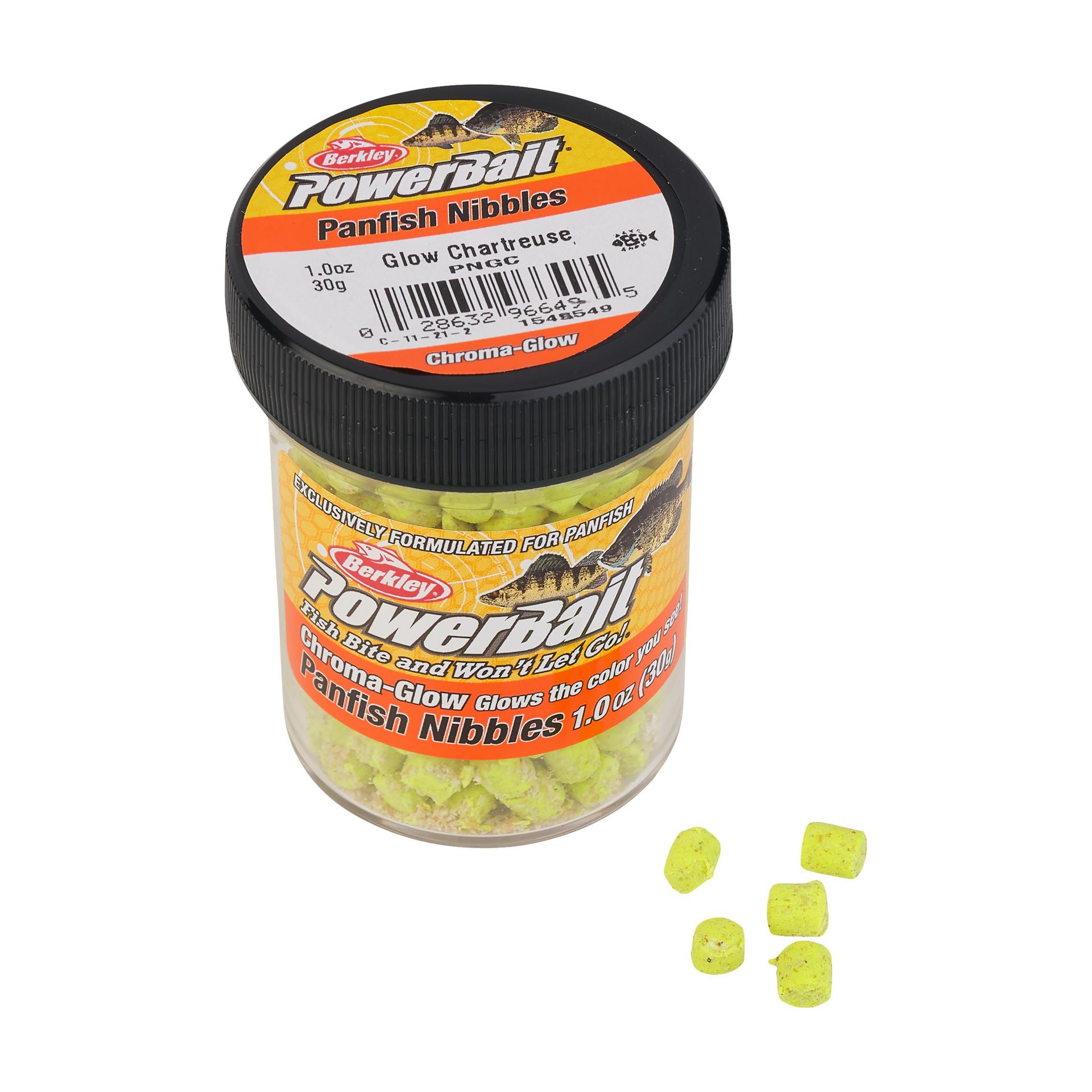

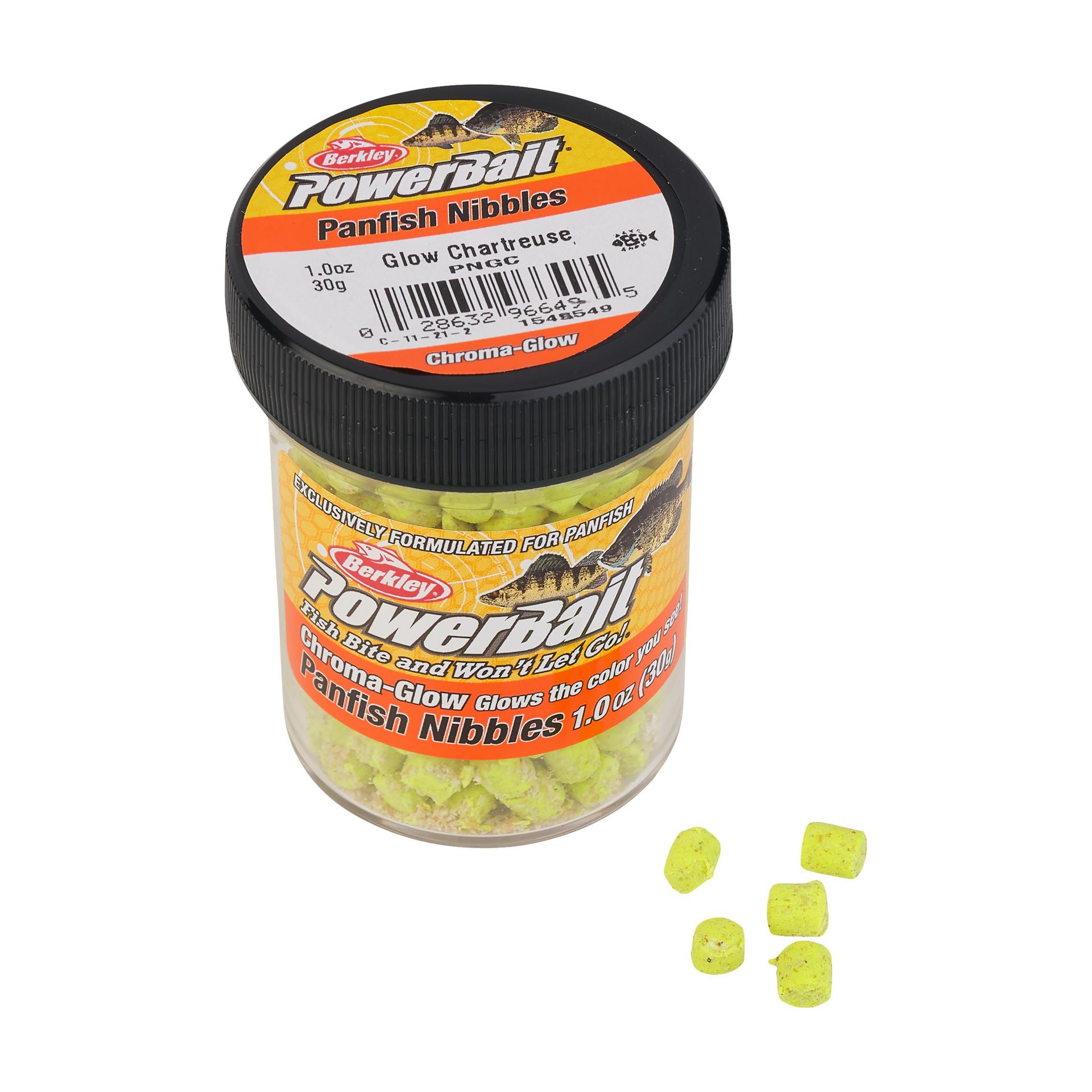

PowerBait® Chroma-Glow Panfish Nibbles

$5.99 -

PowerBait® Panfish Nibbles

$4.99 -

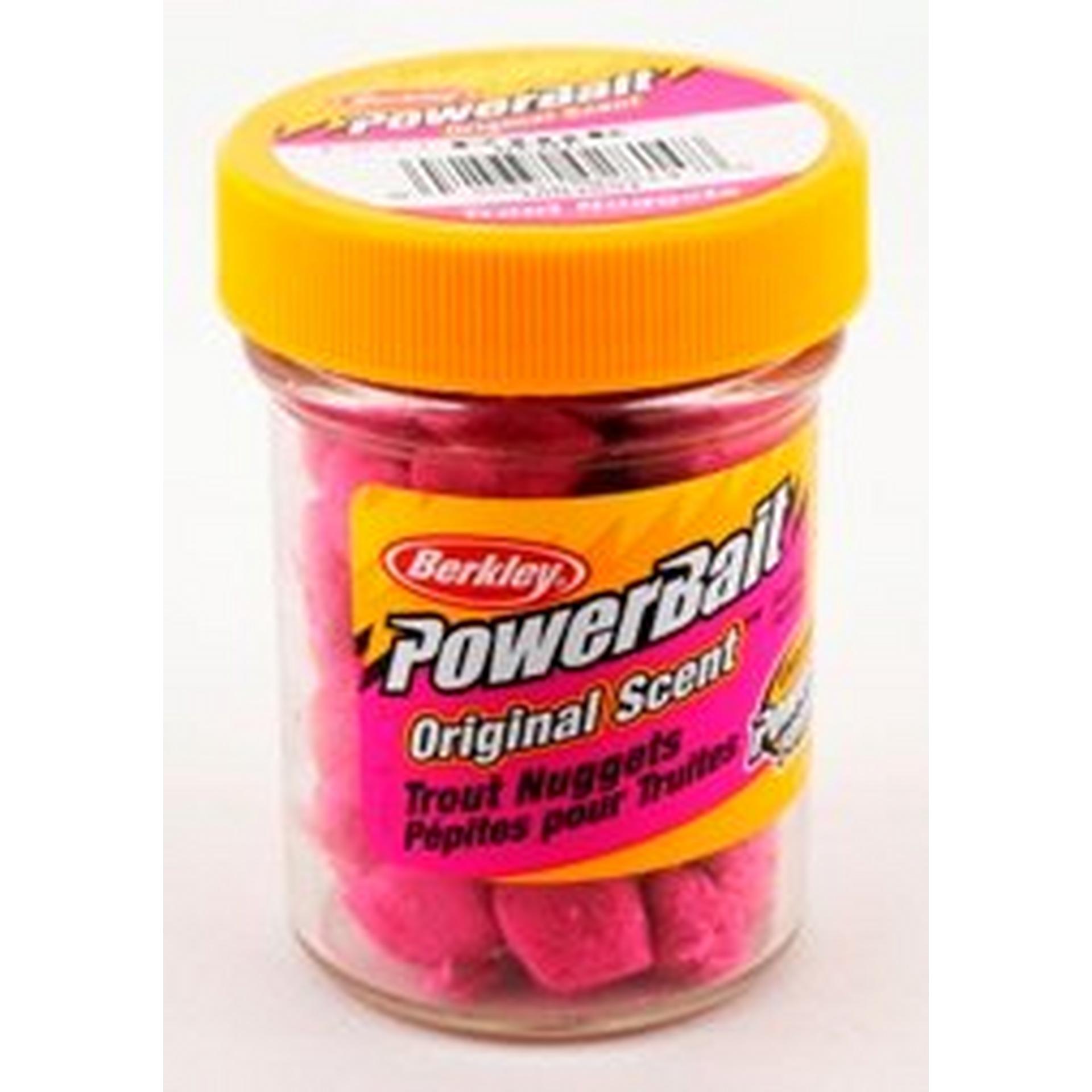

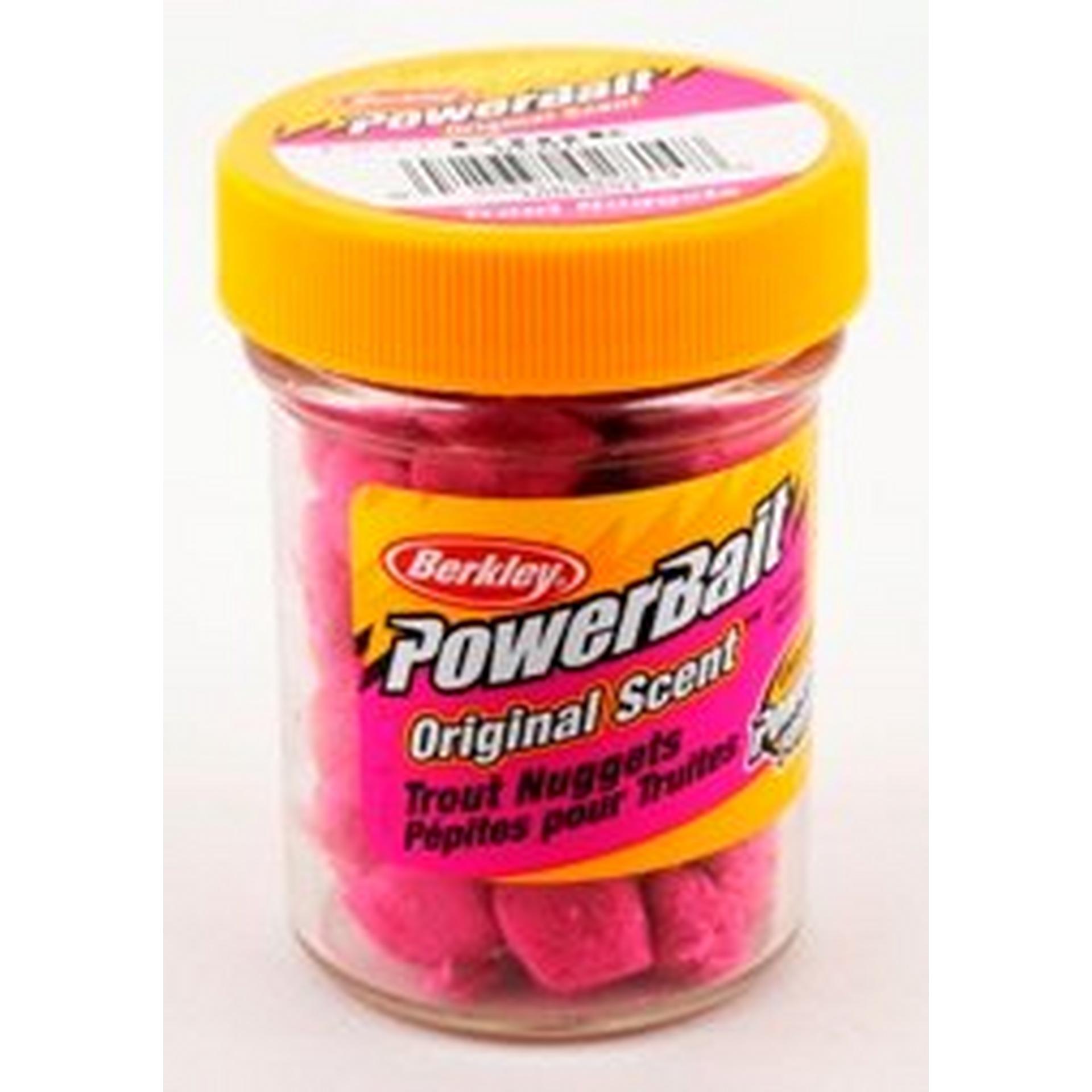

PowerBait® Trout Nuggets

$5.99 -

PowerBait® Trout Bait Assortment

$15.99 -

PowerBait® Catfish Bait Chunks

$6.99 -

PowerBait® Trout Bait

$4.99 -

PowerBait® Chroma-Glow Crappie Nibbles

$5.99 -

PowerBait® Crappie Nibbles

$4.99 -

PowerBait® Trout Bait Twist

$4.99 -

PowerBait® Power Nuggets®

$5.99 -

PowerBait® Glitter Chroma-Glow Dough

$5.99 -

PowerBait® Natural Glitter Trout Bait

$5.99 -

PowerBait® Natural Scent Trout Bait

$5.99 -

PowerBait® Trout Nibbles

$5.99 -

PowerBait® Turbo Dough® Trout Bait

$5.99 -

PowerBait®ChromaGlow Crappie Nibble Asst

$14.99 -

PowerBait® Attractant

$6.99 - $8.99 -

PowerBait® Glitter Turbo Dough®

$5.99 -

PowerBait® Glitter Trout Bait

$5.99 -

PowerBait® Crash Craw

$5.99 -

PowerBait® Craw Fatty

$4.99 -

PowerBait® Crazy Legs Chigger Craw

$5.99

Showing 24 of 105 Products